Our website uses cookies, which makes shopping easier and more personal. More information about this can be found in the privacy policy. If you continue, you consent and agree to the placement and use of Cookies.

Different materials for disposable gloves

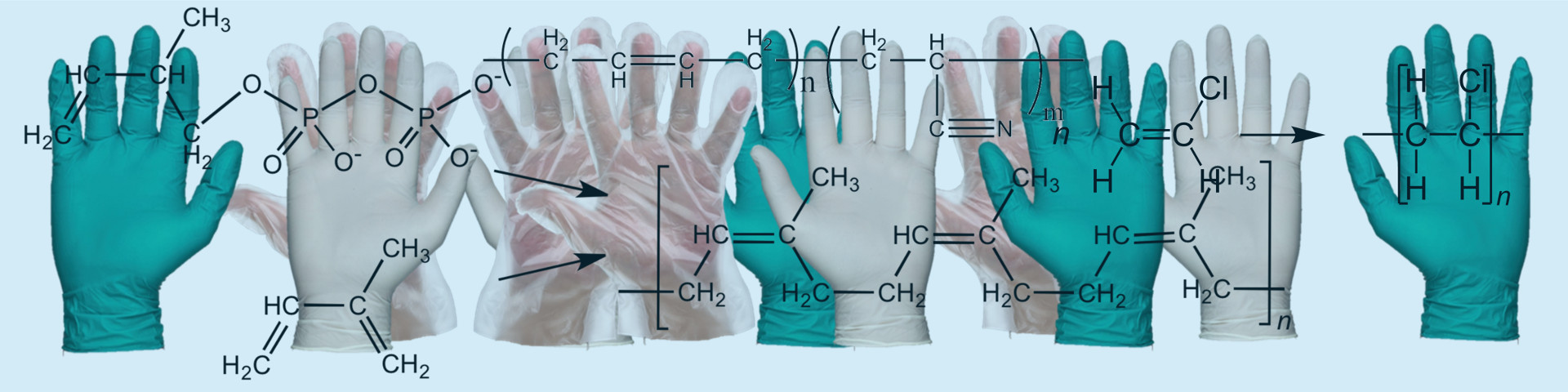

Latex, vinyl, nitrile or PE

Value of the different materials

|

The use of disposable gloves has become a good hygiene practice: in cleaning, catering, care, laboratories, hairdressers, nail studios, tattoo shops and industry, it is impossible to imagine life without them. But it does not always have to be latex. Nitrile, vinyl and polyethylene also deserve a place. |

|

Latex

Latex was the natural raw material when Goodyear first developed gloves as a personal protection device for operations in 1894. These first gloves protected the hands of the medical staff, who otherwise had to use a lot of nasty chemistry to disinfect them sufficiently. But the patients also benefited, as the number of post-operative infections was significantly reduced.

Since then, the use of latex gloves has increased enormously. And as use increased, so did the number of users who reacted allergically to the rubber proteins. In the last century, sensitisation and allergy to natural rubber became a major problem for hospital workers. By the end of the 1990s, nearly 10% of hospital staff had developed a latex allergy.

The development of alternatives such as vinyl and nitrile has fortunately reduced this occupational health and safety problem: allergic sensitisation may sometimes occur after years of exposure to latex, but may also be reduced or even disappear if exposure is substantially reduced. Nevertheless, latex remains the best material for those who attach great importance to the tactile and fine motor control offered by these gloves.

Vinyl

The first widely produced successor to latex was polyvinyl chloride, or PVC or vinyl for short. It is a much easier to produce and cheaper raw material than latex or nitrile. Gloves made of this material are therefore also cheaper and are fine if you only use them for a short time.

They don't last long because vinyl is affected by all sorts of common chemicals, such as those found in most hand creams and cleaners for work surfaces. And you definitely can't use them when you're touching food. In order to get these gloves in shape and make them somewhat flexible, the PVC molecular structure is enriched with phthalates. These dissolve in contact with fats and thus contaminate food.

Nitrile

Nitrile butadiene rubber was developed by BASF and Bayer as a synthetic rubber. It is stronger than latex and also more resistant to oils, natural fats, bases and acids, but slightly less flexible. The material is also safe in contact with food and unlikely to trigger allergic reactions.

As largest rubber producer, Malaysia already had the largest number of latex glove factories, and therefore also became the largest producer of nitrile gloves. Although competition is growing from other Asian countries, sometimes with a slightly different quality of raw material: nitrile for disposable gloves contains approximately 33 to 34% acrylonitrile. If the content is lower (soft nitrile), the gloves are more flexible, but the tensile strength and resistance to chemicals decreases. More acrylonitrile improves the strength and resistance to chemicals, but makes the material less flexible at lower temperatures. The right balance is very important.

Polyethylene

Gloves made of high density polyethylene (HDPE) are not flexible. They are not very comfortable to wear: not comparable to latex or vinyl. Nevertheless, it is perhaps the most common disposable glove. They are cheap, strong, recyclable and resistant to fuels and many other chemicals. So they are perfect for all kinds of jobs where you just want to protect your hands.

Dutch

Dutch